With limited space available for “Short Hold” freight, being stored for short periods at a time, it is important to be efficient in utilizing that time and space.

- Require carrier appointments to minimize surprises and plan the docks accordingly.

- Re-slot positions as necessary to reduce time spent looking for freight when the trucks arrive.

- Utilize cross-docking whenever possible to save time and minimize the chance of damage to the freight.

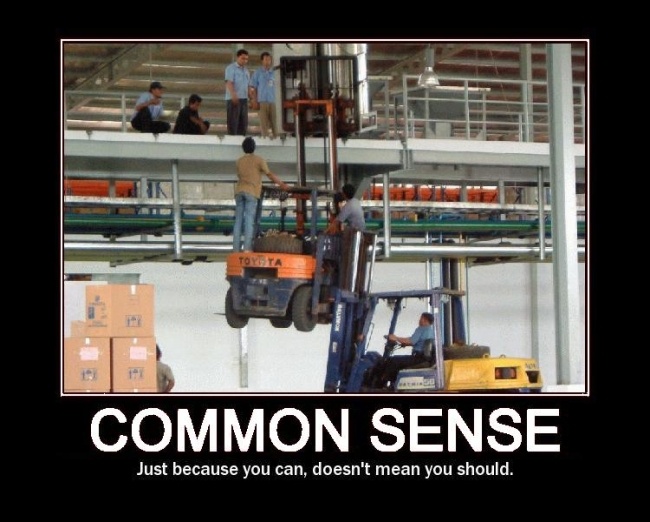

- Avoid common mishaps at loading docks and staging areas to ensure worker safety, prevent:

- Product falling onto someone’s head, feet, arms or legs by conducting safety checks throughout the day

- Poor housekeeping programs that result in congestion by conducting daily inspections of temporary storage arrangements

- Employees jumping from a higher place to a lower one by enforcing safety rules.

- Lifting dock plates and constant adjustment of them by securing dock plates.

- Forklifts or pallet jacks rolling off the dock by never allowing a forklift of pallet jack near the edge of a dock.

- Clean up spills as soon as possible, and remove inventory from aisles when the staff must vacate the area for a short period of time.

- Only trained operators should use equipment such as forklifts, pallet jacks, cranes and hoists.

- Safety equipment must be used at all times – Appropriate eyewear, hair nets and hard hats should be worn when required.

- Clear aisles to make for an efficient flow of inventory.

- Maximize vertical space – The floor space is limited, so it is important to use as much of the available space from floor to ceiling.

- Communication – Communicate effectively and often to be sure the team works together at all times.

BOA Logistics has a team ready to assist with your Dry or Refrigerated LTL shipments!